Concentrating Solar Power (CSP_Lib)

Concentrating Solar Power (CSP_Lib)

Many leading companies working on solar thermal technologies have been using IPSEpro, including DLR, Abengoa Solar, Epuron, SunTechnics, Flagsol, Ciemat-PSA and Iberdrola. They have taken advantage of IPSEpro’s highly flexible software architecture to build their own solar thermal modeling libraries. SimTech, the developers of IPSEpro, and Enginomix, a leading process modeling and consulting firm, have collaborated to develop CSP_Lib, a detailed, robust, commercial-grade IPSEpro model library for solar thermal processes.

Many leading companies working on solar thermal technologies have been using IPSEpro, including DLR, Abengoa Solar, Epuron, SunTechnics, Flagsol, Ciemat-PSA and Iberdrola. They have taken advantage of IPSEpro’s highly flexible software architecture to build their own solar thermal modeling libraries. SimTech, the developers of IPSEpro, and Enginomix, a leading process modeling and consulting firm, have collaborated to develop CSP_Lib, a detailed, robust, commercial-grade IPSEpro model library for solar thermal processes.

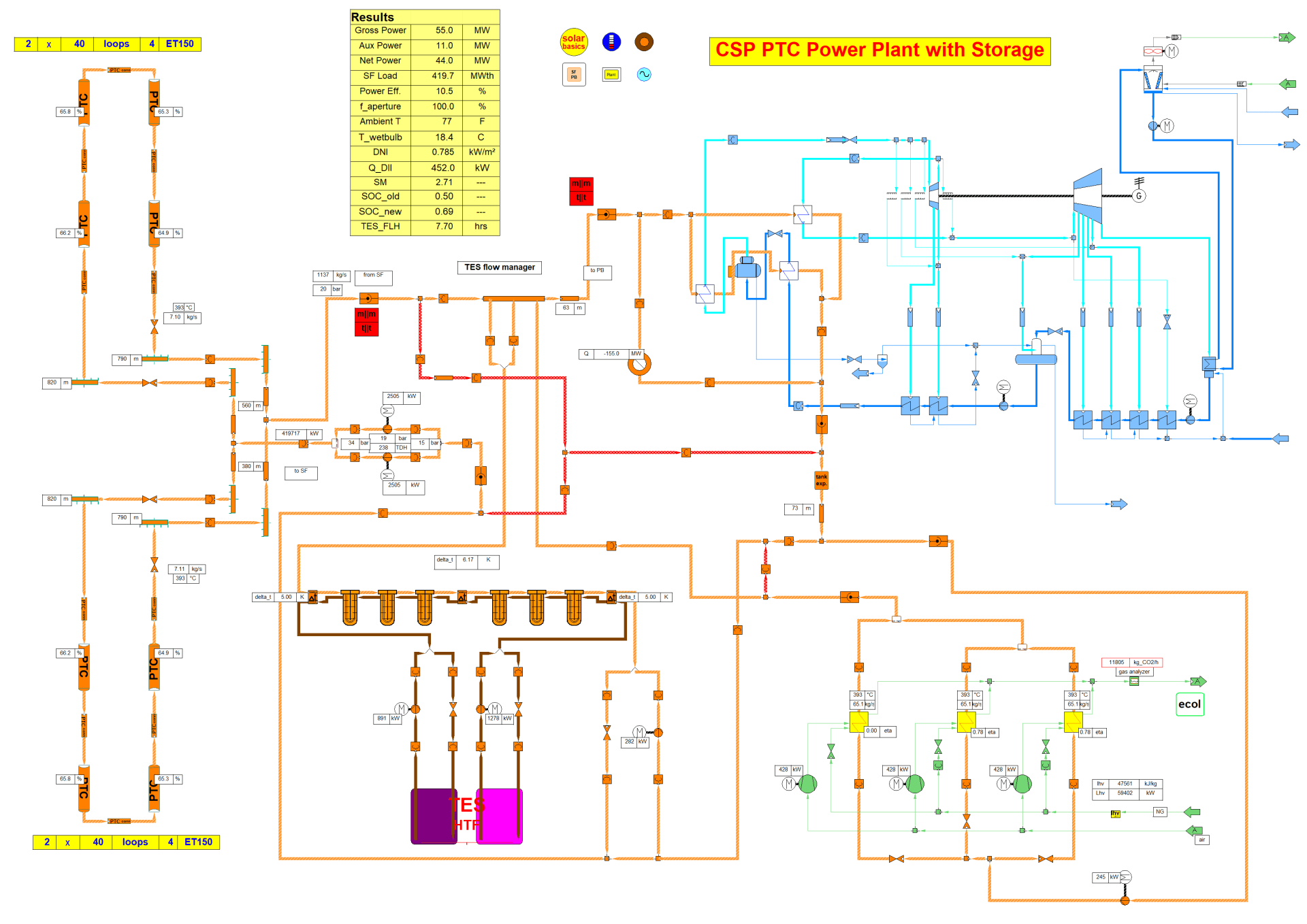

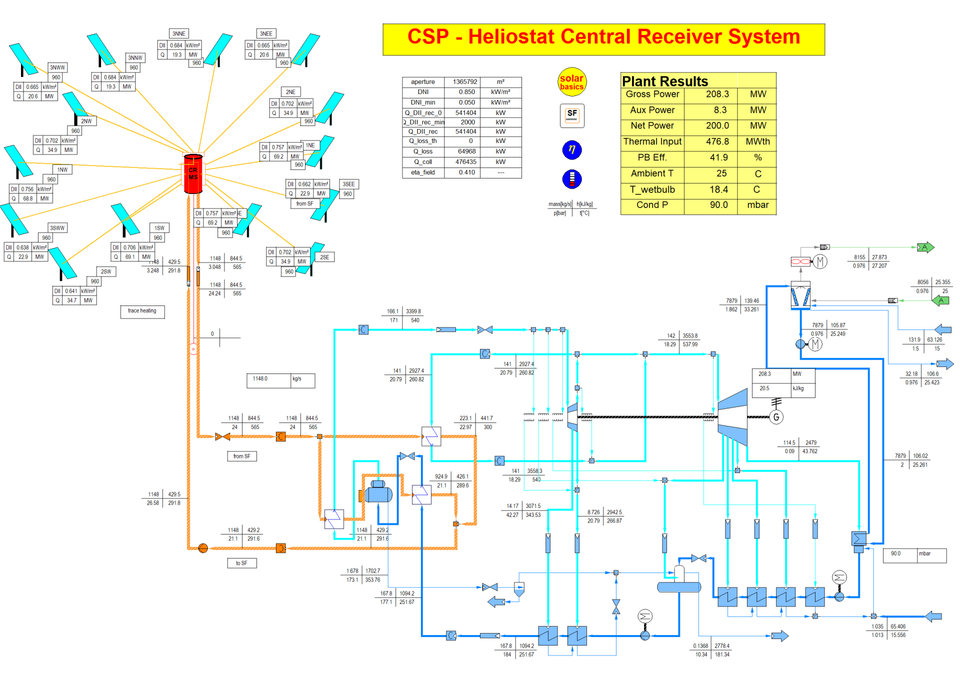

Using IPSEpro and CSP_Lib, you will be able to model all major types of solar thermal processes, including: Parabolic Trough Collectors, Direct Steam Generation, Central Receiver/Heliostat Technologies, Dish Receivers, Fresnel Lens Technologies and Storage Systems. You can also combine CSP_Lib with other IPSEpro libraries for power system modeling, such as EPP_Lib, to provide a best-in-class CSP software package for concentrating solar power technology design, analysis and optimization.

The IPSEpro Solar Thermal library includes physical properties for gas streams, water/steam streams, and heat transfer fluids (HTFs) used in many solar thermal technologies. With IPSEpro’s easy-to-use Windows interface, you simply select the fluids you need for your cycle from a pull-down list. And, if you need to, you can use IPSEpro’s MDK to modify or expand the thermal property system in your library, for example to add additional HTF fluids.

Using IPSEpro and CSP_Lib, you will be able to model all major types of solar thermal processes, including: Parabolic Trough Collectors, Direct Steam Generation, Central Receiver/Heliostat Technologies, Dish Receivers, Fresnel Lens Technologies and Storage Systems. You can also combine CSP_Lib with other IPSEpro libraries for power system modeling, such as EPP_Lib, to provide a best-in-class CSP software package for concentrating solar power technology design, analysis and optimization.

The IPSEpro Solar Thermal library includes physical properties for gas streams, water/steam streams, and heat transfer fluids (HTFs) used in many solar thermal technologies. With IPSEpro’s easy-to-use Windows interface, you simply select the fluids you need for your cycle from a pull-down list. And, if you need to, you can use IPSEpro’s MDK to modify or expand the thermal property system in your library, for example to add additional HTF fluids.

With IPSEpro’s Process Simulation Environment (PSE), you create a process model based on the components from a library. A user-friendly flowsheet editor allows you to build your process models graphically. You simply select the component models from a menu, place them in your scheme, and connect them appropriately. You can enter all data directly in the flowsheet. IPSEpro provides efficient data management, powerful mathematical methods and an intuitive graphic user interface, so that you can fully concentrate on the technical aspects of your models.

With IPSEpro, all model equations in the libraries are visible allowing you to review them and decide if they satisfy your requirements. Most component models include equations for predicting design and off-design behavior. You can combine any of the standard model libraries. The source code for all of the libraries is provided, permitting you to have the option to use them “as they are” or as a basis for creating your own customized versions.

With IPSEpro’s Process Simulation Environment (PSE), you create a process model based on the components from a library. A user-friendly flowsheet editor allows you to build your process models graphically. You simply select the component models from a menu, place them in your scheme, and connect them appropriately. You can enter all data directly in the flowsheet. IPSEpro provides efficient data management, powerful mathematical methods and an intuitive graphic user interface, so that you can fully concentrate on the technical aspects of your models.

With IPSEpro, all model equations in the libraries are visible allowing you to review them and decide if they satisfy your requirements. Most component models include equations for predicting design and off-design behavior. You can combine any of the standard model libraries. The source code for all of the libraries is provided, permitting you to have the option to use them “as they are” or as a basis for creating your own customized versions.

IPSEpro’s powerful PSXLink

module enables you to integrate your IPSEpro-PSE projects with Excel worksheets. Using PSXLink, you can run scenario calculations to calculate the performance of your solar thermal plants hourly through the course of an entire year. PSXLink includes a link to standard meteorological data sets, such as TMY2, so that you can select a location and automatically apply the appropriate ambient and solar insolation values, based on location and time, as you calculate yearly performance. You can run cases once an hour for an entire year (365×24 runs), you can use monthly averaged data (12×24 runs), or you can configure and run your own arbitrary operating profiles.

IPSEpro’s powerful PSXLink

module enables you to integrate your IPSEpro-PSE projects with Excel worksheets. Using PSXLink, you can run scenario calculations to calculate the performance of your solar thermal plants hourly through the course of an entire year. PSXLink includes a link to standard meteorological data sets, such as TMY2, so that you can select a location and automatically apply the appropriate ambient and solar insolation values, based on location and time, as you calculate yearly performance. You can run cases once an hour for an entire year (365×24 runs), you can use monthly averaged data (12×24 runs), or you can configure and run your own arbitrary operating profiles.

RECEIVE MORE INFORMATION ABOUT ENGINOMIX PRODUCTS AND SERVICES:

Enter your information below to access sample models and to receive more information about Enginomix Products and Services.

Thank you for contacting us.

We will get back to you as soon as possible

We will get back to you as soon as possible

Oops, there was an error sending your message.

Please try again later

Please try again later