PSE: Process Simulation Environment

PSE: Process Simulation Environment

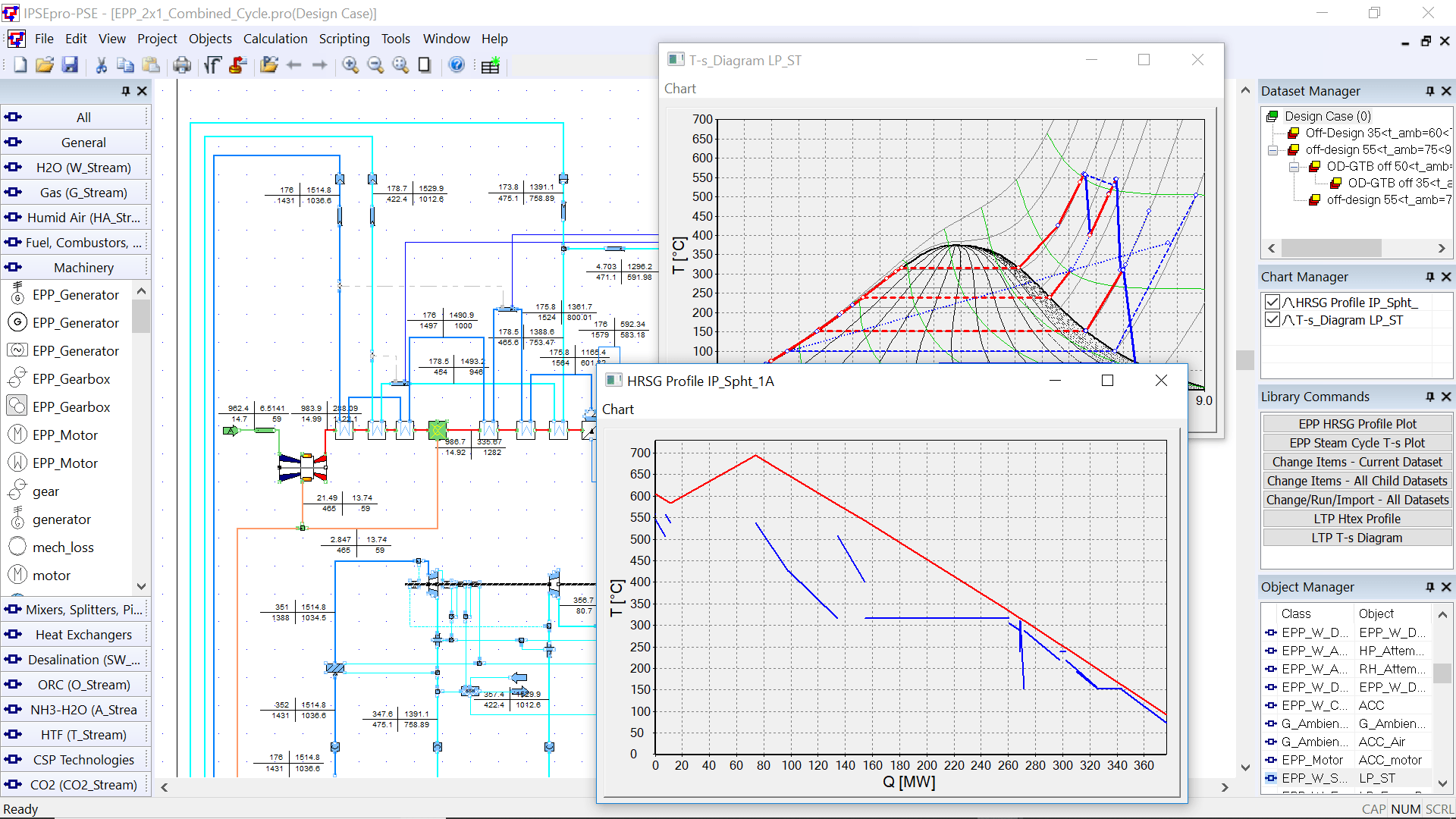

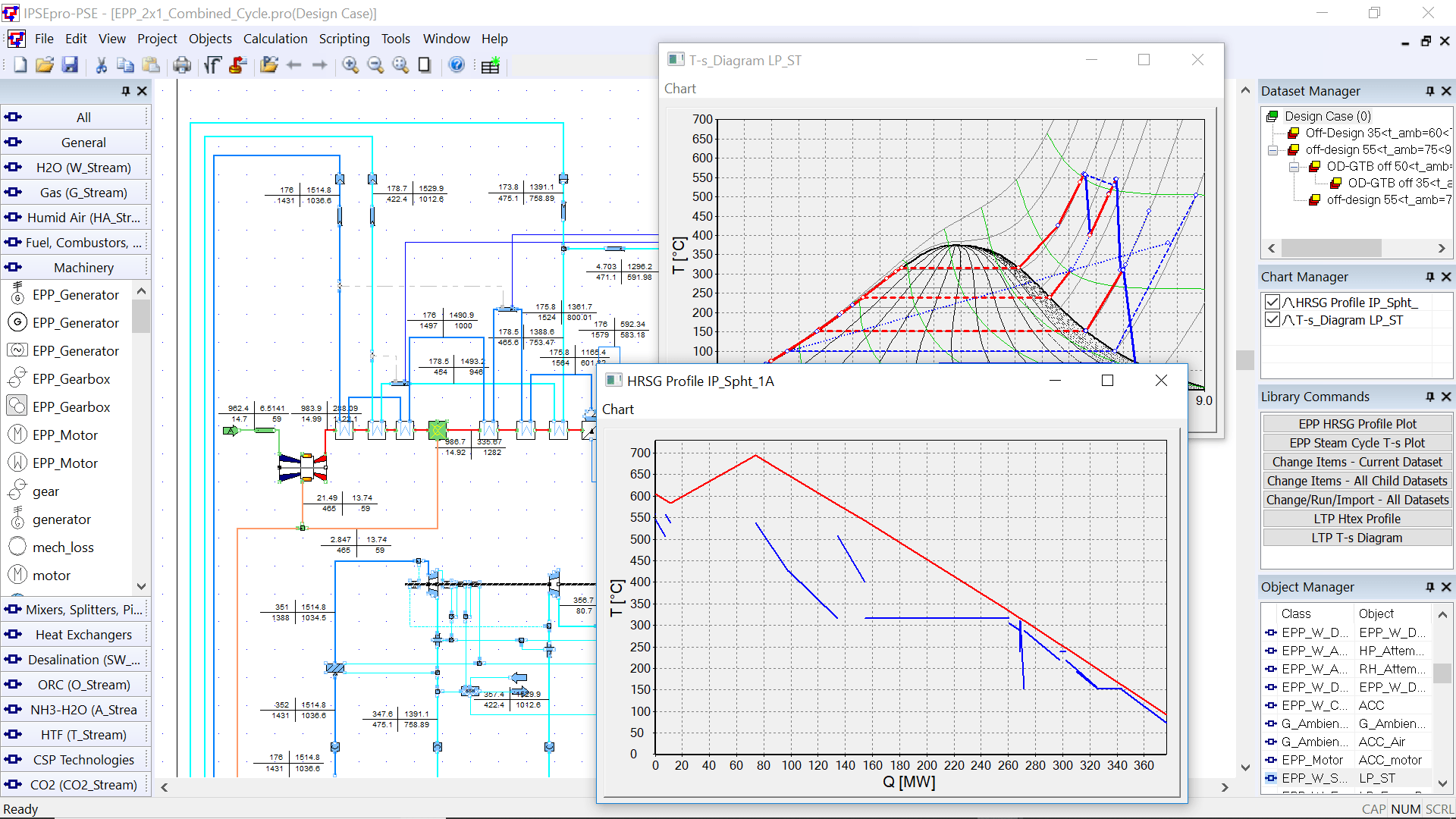

PSE is IPSEpro’s Process Simulation Environment. With PSE you create a process model (flowsheet) using components (icons) from an IPSEpro model library.

PSE is IPSEpro’s Process Simulation Environment. With PSE you create a process model (flowsheet) using components (icons) from an IPSEpro model library.

Using PSE

PSE provides a user-friendly flowsheet editor for setting up process models. The user selects the required components from the library menu and arranges them appropriately. The user enters all process data directly in the flowsheet. The results are directly displayed on the scheme. PSE generates output protocols automatically, at the end of a simulation run.

PSE solves simulation problems using an equation-oriented approach. Optimized mathematical methods guarantee fast and accurate calculations. To solve a system of equations, PSE adopts a 2-phase approach:

Analysis: In the analysis phase, PSE first checks the model for errors in the process specifications. If the specifications are correct, it determines the optimum solution method.

Numerical Solution: In this phase PSE solves the equations with the numerical methods pre-defined by the analysis phase.

With its available add-on solver modules, the PSE process model simulation software can be used to tackle both steady-state simulation and dynamic simulation problems, using the same, robust, user-friendly modeling environment.

Using PSE

PSE provides a user-friendly flowsheet editor for setting up process models. The user selects the required components from the library menu and arranges them appropriately. The user enters all process data directly in the flowsheet. The results are directly displayed on the scheme. PSE generates output protocols automatically, at the end of a simulation run.

PSE solves simulation problems using an equation-oriented approach. Optimized mathematical methods guarantee fast and accurate calculations. To solve a system of equations, PSE adopts a 2-phase approach:

Analysis: In the analysis phase, PSE first checks the model for errors in the process specifications. If the specifications are correct, it determines the optimum solution method.

Numerical Solution: In this phase PSE solves the equations with the numerical methods pre-defined by the analysis phase.

With its available add-on solver modules, the PSE process model simulation software can be used to tackle both steady-state simulation and dynamic simulation problems, using the same, robust, user-friendly modeling environment.

RECEIVE MORE INFORMATION ABOUT ENGINOMIX PRODUCTS AND SERVICES:

Enter your information below to access sample models and to receive more information about Enginomix Products and Services.

Thank you for contacting us.

We will get back to you as soon as possible

We will get back to you as soon as possible

Oops, there was an error sending your message.

Please try again later

Please try again later